Meet a genuine Innovator, a value-added Producer, a customer-centric Supplier!

We are the world leader in the production of perforated and reinforced stretch films in the area of innovative flexible packaging for more than 25 years, and we do what it takes to deliver reliable products that fulfill your needs.

Innovation is our way to do it!

- We are one of the top stretch film producers offering a wide range of high-quality wrapping solutions.

- We value innovation and always aim to be at the cutting edge of sustainable packaging.

- We are the manufacturer & supplier you have been searching for.

We have entered the agricultural market for Silage Bale Wrap and are looking forward to sharing our expertise with our new partners through innovative & sustainable products.

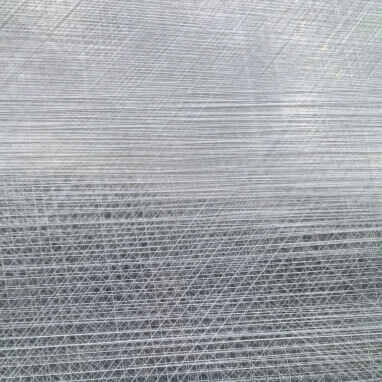

Our Fiber4SilageTM is A novelty in Silage Baling – A true field of possibilities!

- A brand-new fiber reinforced multilayer film that creates a protection grid around the bale ensuring tight wrapping along with consistent film stretching.

- The superior film strength due to this unique structure prevents tearing and breakages during bale wrapping.

- The power of the fibers in baling makes this silage wrap totally irresistible!

The reasons behind our innovative technology are rooted in our deep understanding of complex customer demands, our passionate team of experts, and our ongoing research.

Τhe Ultimate Silage Stretch wrap.